What are the specific technological processes of Sunny glassware Products to produce glass candle ho

There are many types of glass candle holders, and they play a pivotal role in every corner.In addition to the glass candle holders and glass cups used to make candles,there are many types of art decorations that are used in our daily contact.Sunny Group has offered glassware since 1992 with all kinds of products being exported to more than 30 countries and regions.If you want to understand the technological process of Sunny glassware candle holder, you may wish to read it.

The craft of vitreous candlestick is divided into a variety of types, among them those who blow make a product are divided into: machine blow and artificial blow make. The machine blowing is divided into ordinary machine blowing and pressure blowing.

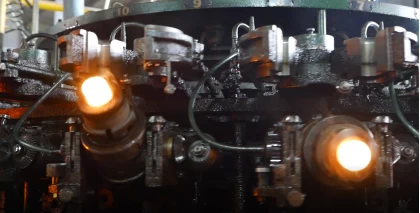

Machine blowing process: the material is fed into the abrasive tool from the forehearth, and the glass frit is blown into the abrasive tool while turning, bursting, and annealing.

The characteristics of machine blown products are:

① Machine-blown products can be made with a small mouth or a small mouth.

② Taking the center line of the cup as the criterion, the cup formed by one rotation of the radius (must be able to rotate in the mold) can be blown by the machine. The cup body must not have patterns or other logos. The shape of the cup body cannot be a polygonal structure.

③ Machine-blown products have a hot burst ring on the cup mouth and a dripper.

④ There will be abrasive lines on the cup of machine-blown products (because the material is rotated in the abrasive, and the abrasive pattern is horizontal on the cup body.

⑤ The wall thickness of machine-blown products is generally around 1-1.5MM, and generally between 1-1.2MM. The wall thickness of the Euro 90 machine can be 1.8MM (mainly Deli and bows and arrows, Libi and their machines can achieve this wall thickness.

⑥ Bottom thickness is about 0.5-2CM.

⑦ Wall thickness is getting thicker from top to bottom.

⑧ The bottom of the machine-blown cup is not particularly flat, and some may have some lines.

Pressure blowing process: material from the feed channel into the abrasive - glass material in the abrasive blowing molding (no rotation) - explosion - annealing

Pressure blowing product features:

(1) If there is a pattern or other LOGO on the body of the machine blown product cup, the pressure blowing process is needed.

② If it is a polygon shape, it is also necessary to use the pressure blowing process

(3) Because the material in the abrasive is not rotating, so there will be no abrasive grain, but there will be seam line. If the abrasives are not handled properly. The body will not be smooth.

(4) In addition to the above characteristics, other characteristics and blowing characteristics of the same (also have hot explosion, wall thickness, bottom thickness and blowing is like, there are also dropper)

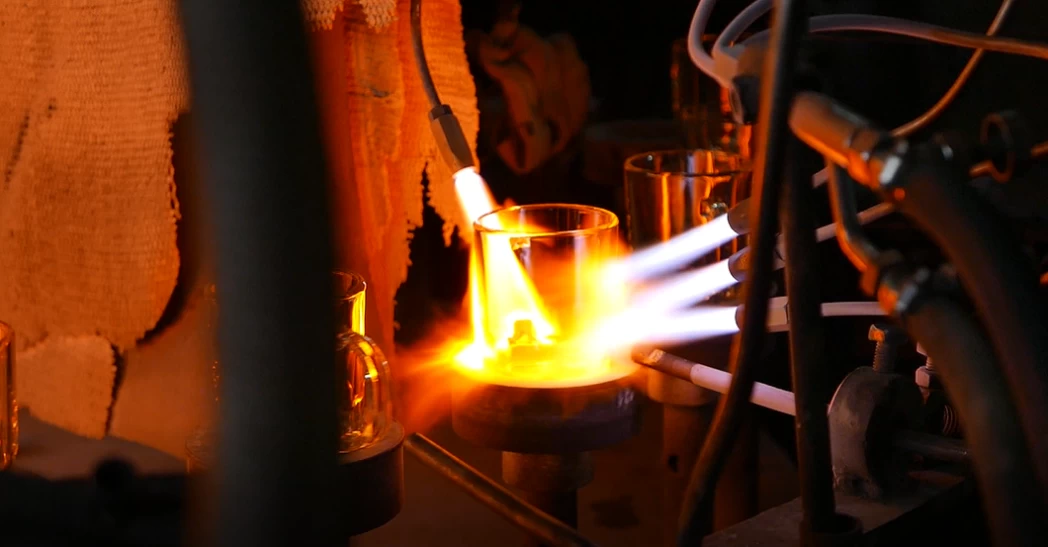

Manual blowing process: manual material from the furnace - manual in the grinding tool through iron pipe blowing - mouth treatment - annealing

Characteristics of manual blowing products:

(1) There will be errors in product specifications. (Wall thickness + weight + capacity, etc.)

② Machine pressure or machine blown products can be made by manual blowing process, manual blowing products may not be made by machine pressure or machine blowing process.

(3) Artificial blowing products mouth processing is divided into grinding mouth, burning mouth, hot explosion mouth

Nowadays, people savour tall, the handicraft of vitreous candlestick also gets people more and more chase after in both hands, it is the adornment in the home of ordinary people promoted grade and artistic feeling.Focusing on luxury fragrance products in the latest 10 years, Sunny Glassware is the supplier of 80% fragrance brands in the United States.