How To Leverage AI To Enhance Traditional Decal Technology For Prestigious French Wineries

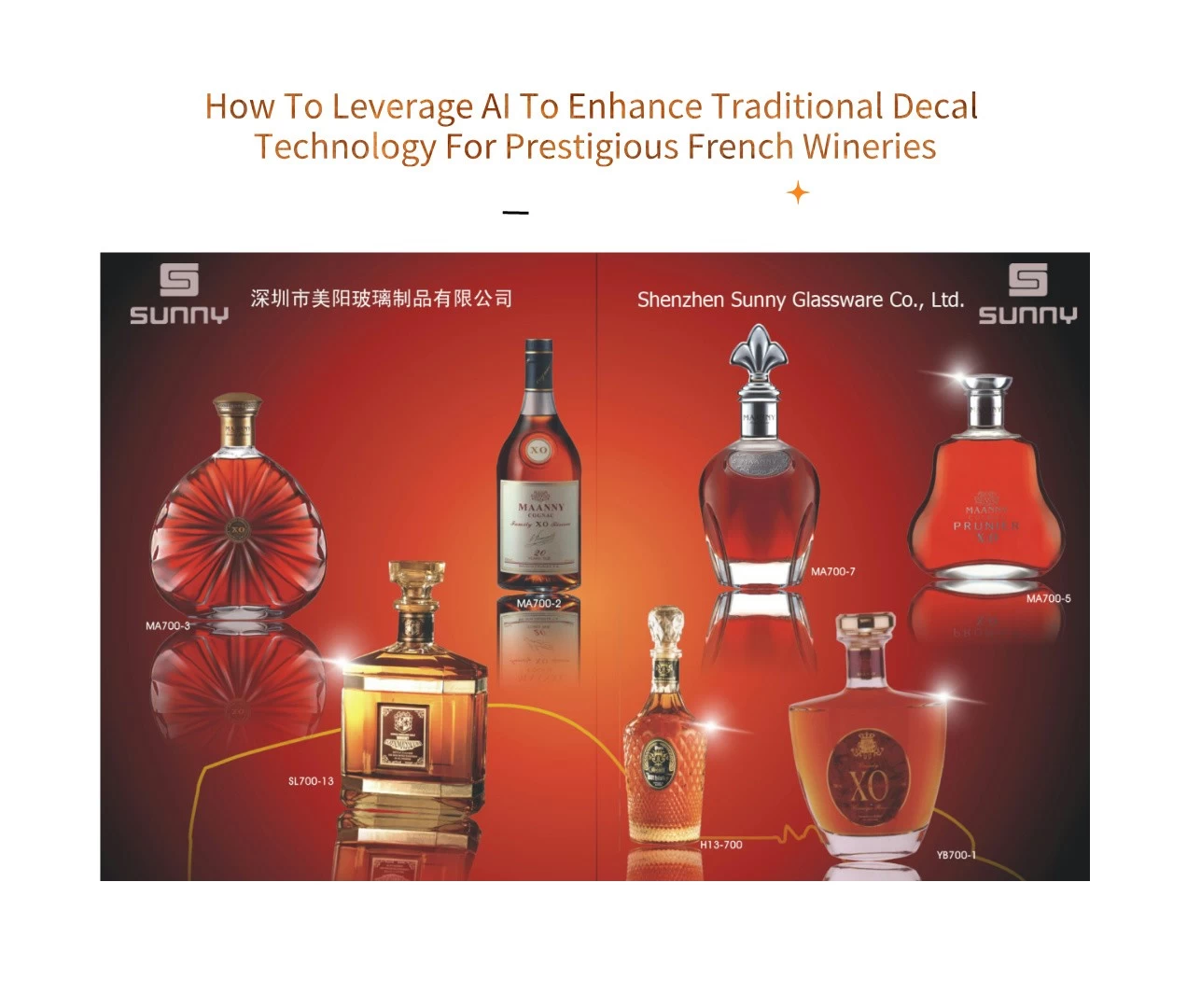

Our client, Mr. Joe, the proprietor of a renowned French winery, had high expectations for a specific carved wine bottle. Initially, he sought manufacturing services from both French and American suppliers but was unsatisfied with their offerings. After viewing a YouTube video showcasing the intricate process of creating such bottles, he contacted Sunny Glassware via email, expressing his desire for Sunny Glassware to develop a refined and durable decal process that would enhance the brand value of his wines.

Through email correspondence, we understood that Mr. Joe's desired applique effect required not only exquisite patterns but also emphasized durability. Traditional decal processes often suffer from issues such as fading and peeling during prolonged alcohol exposure and transportation, which is unacceptable for customers who demand exceptional quality. Additionally, ensuring a perfect fit between the decal and the glass surface without any bubbles or irregularities posed a significant challenge.

In response to these challenges, Sunny Glassware remained undeterred. Our award-winning design team, trusted by prestigious brands like NEST, collaborated with senior craftsmen to thoroughly analyze the strengths and weaknesses of traditional decal techniques. By integrating DeepSeek AI technology, we innovated and developed a specialized decal material that bonds tightly with bottle glass at high temperatures, forming a robust layer resistant to peeling. We also employed advanced laser engraving technology to ensure precise pattern replication.

After multiple rounds of trials and improvements, our design department successfully developed a new decal process that perfectly adheres to the bottle body while maintaining vibrant and intact patterns even after prolonged alcohol exposure. During the sample production phase, we strictly adhered to the customer's design specifications, meticulously crafting every detail. To verify the durability of the decals, we conducted rigorous tests under various extreme conditions, including prolonged alcohol soaking, high-temperature baking, and vigorous shaking.

Upon receiving the samples, Mr. Joe expressed great surprise and satisfaction with the decal process and promptly placed a bulk order via email. To ensure production efficiency and product quality, we utilized automated production lines and stringent quality control systems. We maintained close communication with the client, regularly sharing production progress and quality control updates. This transparent cooperation model enhanced customer trust and secured long-term stable orders and collaboration opportunities.

Today, Sunny Glassware has enjoyed an eight-year partnership with the French winery, and our decal wine bottles have become a highlight of their brand. This successful case study not only demonstrates our technical prowess and innovation capabilities but has also garnered widespread acclaim within and outside the industry.