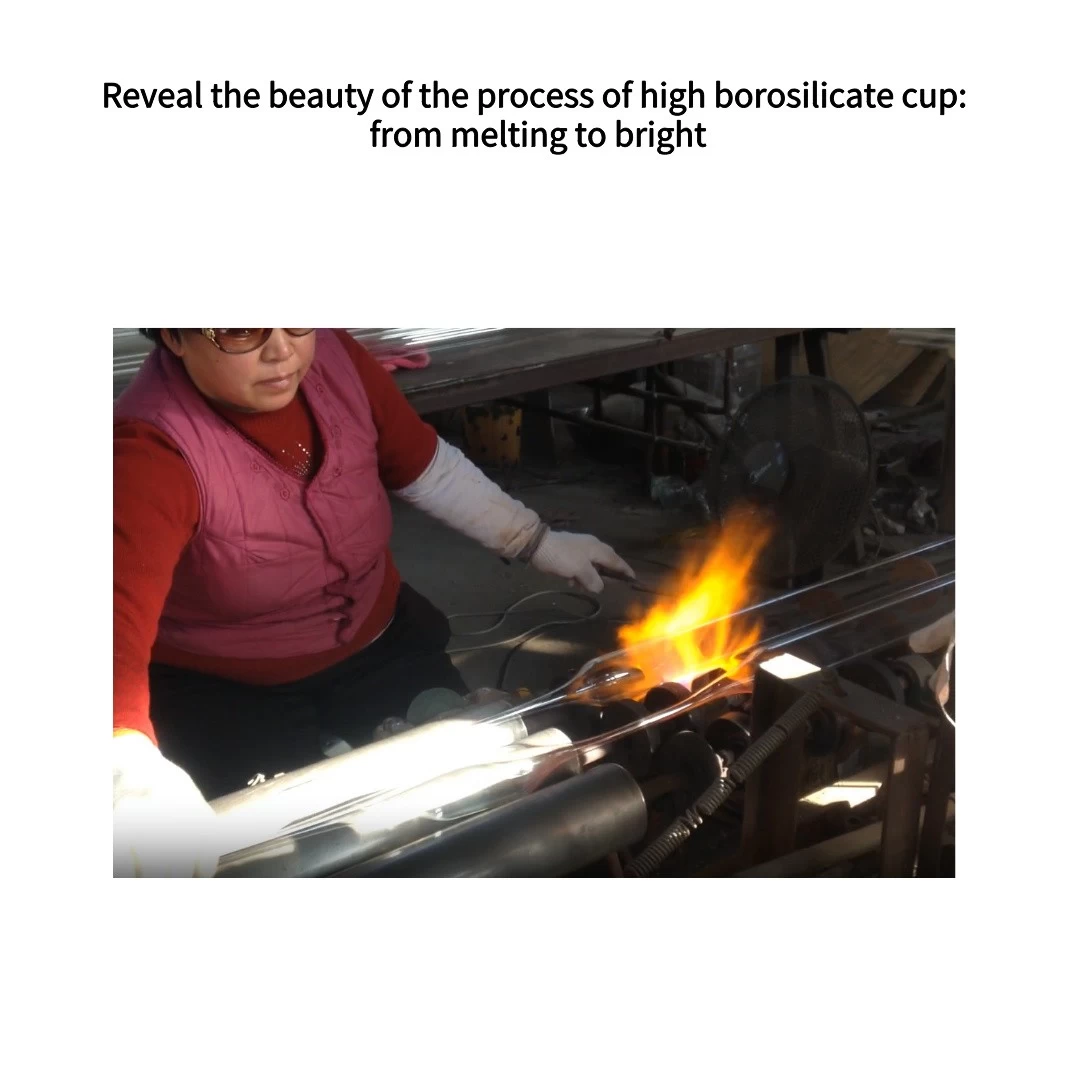

Reveal the beauty of the process of high borosilicate cup: from melting to bright

Have you ever wondered about that crystal clear, extraordinary high borosilicate cup around you? Today, Sunny Glassware takes you into the world of high borosilicate cups to explore the mystery behind it.

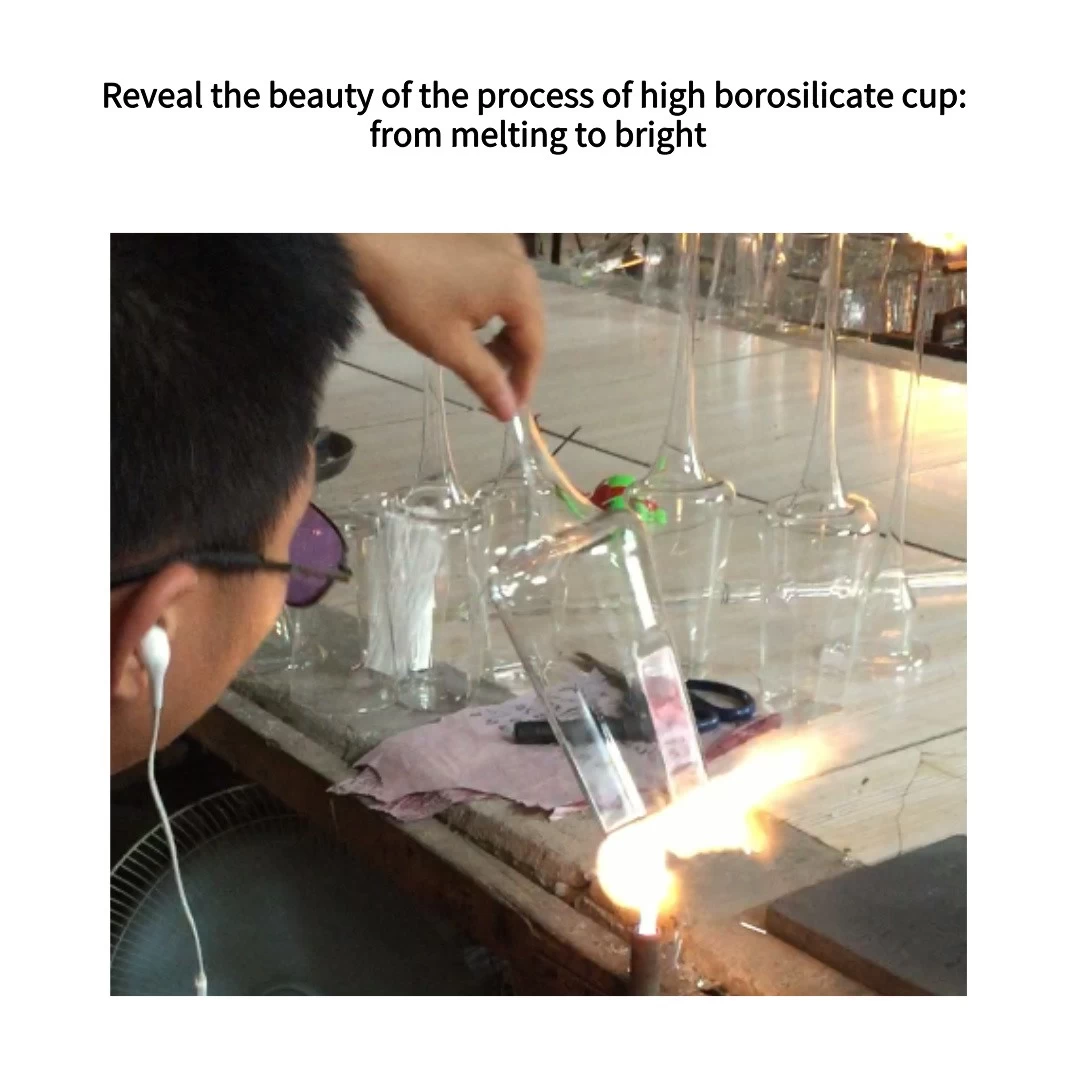

Melting: Baptism of fire

The beginning of the high borosilicate cup is an intimate encounter with fire. Selected raw materials such as borax and silica sand are fed into high-temperature furnaces under strict proportional control. There, they undergo high temperature melting above 1500 ° C and gradually merge to form a clear and transparent glass liquid.

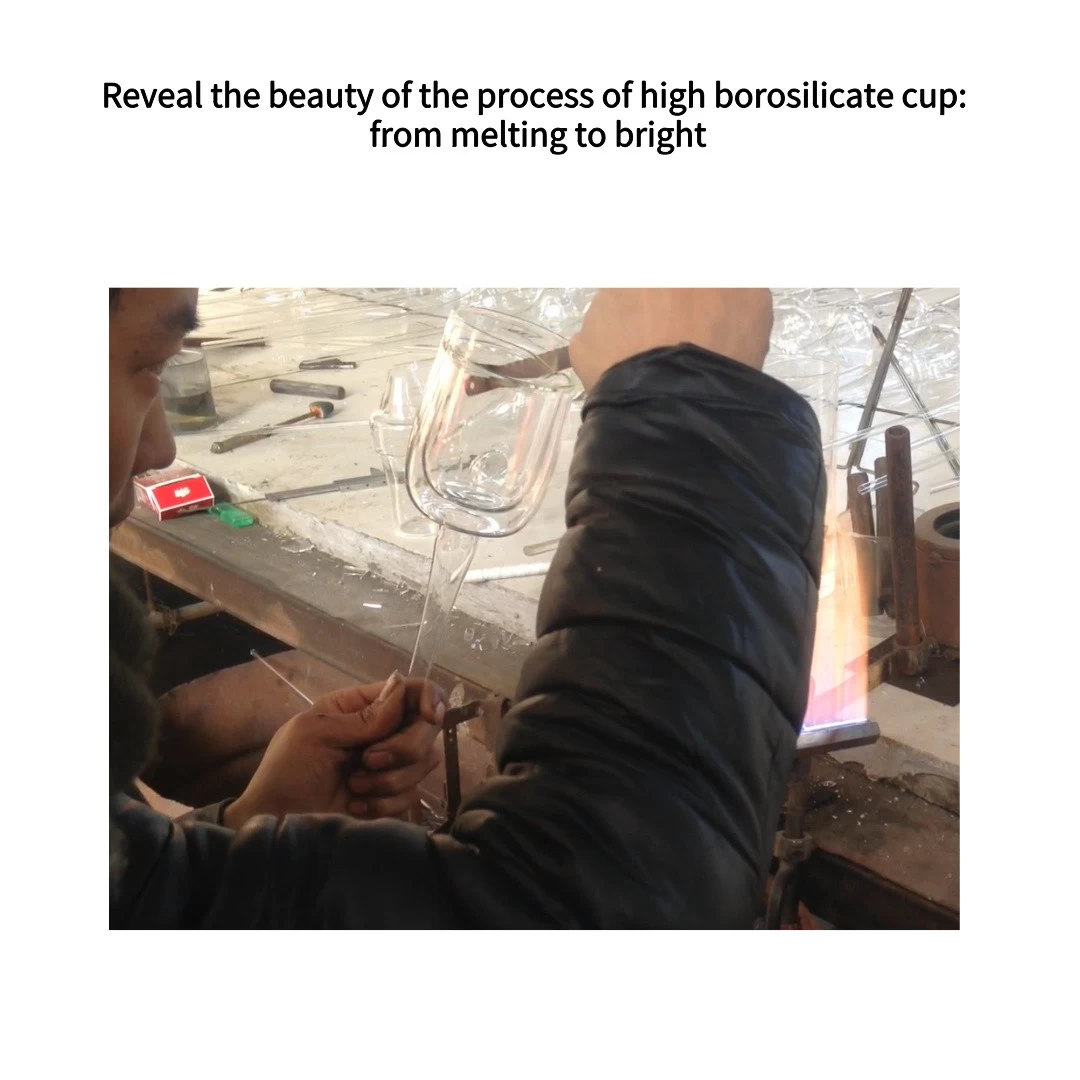

Molding: The carving of art

The liquid glass is rolling in the furnace, waiting for its next fate. Through exquisite molding processes such as blowing and pressing, the liquid glass is shaped into the familiar cup shape. Every detail is carefully polished to ensure that every high borosilicate cup is flawless.

Annealing: quality enhancement

After forming the high borosilicate cup, it also needs to undergo an important annealing treatment. This step is not only to eliminate the internal stress of glass products, but also to improve its stability and durability. Annealed high borosilicate cup are more durable and can accompany us through every beautiful moment.

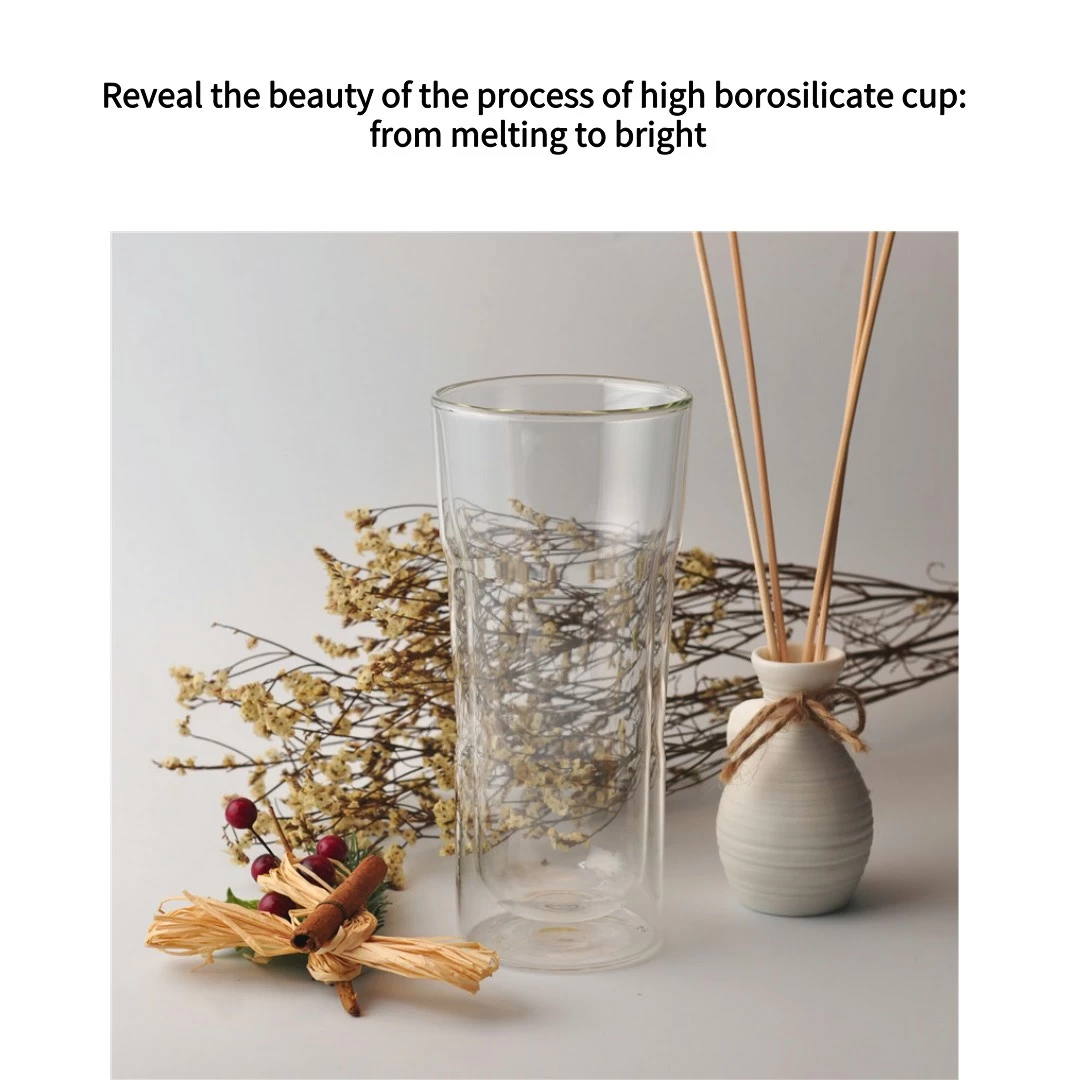

Bright: Dance of light

When the high borosilicate cup is finally presented in front of us, you will find that it is not only a cup, but also a work of art. The clear and transparent cup body shines in the sun, as if dancing light and shadow are telling its story.

The beauty of the process of high borosilicate cup of Sunny Glassware comes from the strict screening of raw materials, the exquisite control of the process and the unremitting pursuit of quality.

Now, when you hold that crystal clear high borosilicate cup, do you cherish it more? Let us taste the beauty of art in this cup and feel the infinite possibilities of life.