What is the process flow of ceramic of Sunny glassware products?

Ceramics can be seen everywhere in life. Whether it is candlesticks or cups, these household gadgets have ceramic types. There are three kinds of ceramic processes, and each kind of ceramic process has its unique advantages. In order to let everyone know more about ceramics, sunny glassware will introduce the types of ceramics, forming methods and process flow of ceramic candlesticks.

The types of ceramics are divided into low-temperature porcelain, medium temperature porcelain and high-temperature porcelain. Low temperature porcelain, also known as dolomite, is generally suitable for hand-painted and diversified surface treatment. Low temperature porcelain is usually fired at 780 degrees. After coloring, it is usually baked at 680 degrees and then glazed. The glaze firing temperature is 1030-1050 degrees. The shrinkage ratio of low-temperature porcelain is 7%, and the water absorption is 17%-2.

Medium temperature porcelain is also called semi porcelain, which is suitable for colored glaze, kiln change glaze and colored paper in glaze. Generally, there are two firing methods, one-time clay embryo glaze firing. Some factories also choose plain firing before glaze firing. The plain firing temperature is generally 780, and the glaze firing temperature is 1180-1220. The shrinkage ratio of medium temperature porcelain is generally 12%, and the water absorption is 1%-3%.

High temperature porcelain is also called white porcelain. There is no special glaze change. The surface treatment is usually transparent glaze with decals. Firing method: the clay embryo is dry and directly glazed. The firing temperature is 1280-1320. The basic porcelain glaze is relatively hard. The water absorption of high-temperature porcelain is zero.

Ceramic forming methods include platform grouting, high-pressure grouting, rolling and stamping.

The platform grouting is generally an irregular three-dimensional part, and the operational life of the mold is 60 times.

Pour slurry demould

High pressure grouting is generally flat plate products without depth, the service life of the mold is 120 times/mold.

Pour slurry demould

Rolling grouting is generally more neat, the service life of the mold is 250 times.

Molding demoulding attachment

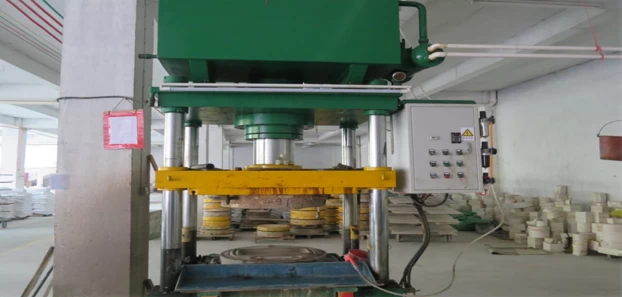

Stamping molding is generally relatively shallow, irregular and large products are characterized by high yield, good density and good smoothness. Stamping die can be used 4000 times.

Molding mold release

The technological process of ceramic candlestick:

1 molding 2 demoulding 3 plaster slurry

4 KS mother mold 5 production mold 6 platform grouting

7 high pressure grouting 8 rolling grouting 9 stamping molding

10 cutting 11 tire repair 12 tire washing

13 mud inspection 14 plain burning 15 plain inspection

16 color painting 17 baking color 680 degree 18 glazing

19 glaze burning 1080-1320 20 glaze inspection 21 packaging

The above are the types of ceramics, forming methods and process flow of ceramic candlesticks introduced by sunny glassware. Have you got a certain understanding of the types of ceramics, forming methods and process flow of ceramic candlesticks? I hope sunny glassware introduction can help you better understand the knowledge of ceramic candlesticks.Sunny Group has offered glassware since 1992 with all kinds of products being exported to more than 30 countries and regions.